- Home

- About Us

- Products

- Cases

- News

- Contact Us

-

Hotline: 400-086-6258

Our company invested in the industrial production research of " Continuous Screw Flight" in 2000, and achieved industrialization success in China the following year. The product was awarded "High-tech Product of Jiangsu Province, China".

1. The spiral forming speed is fast, the production efficiency is high, the material utilization rate is high, the overall rigidity is good, and the overall strength is high. ;

2. The welding assembly is convenient and quick, and the overall strength is good;

3. The thickness of the outer edge is about 1/2 of the thickness of the inner hole, but after hardening by rolling and cooling, the hardness of the outer edge is more than doubled, which correspondingly compensates for the wear resistance of the outer edge;

4. Heat treatment can be carried out according to requirements to improve the surface hardness of the blade and improve the wear resistance;

5. The forming size is limited, only the spiral blade of low carbon steel material with a thickness ≤ 8mm and the maximum radius difference (outer diameter/2-inner diameter/2) ≤ 165mm can be formed;

6. The one-time debugging before production consumes high materials, which is not suitable for one-time small batch supply of one specification, and there is a minimum order quantity requirement.

SPHC

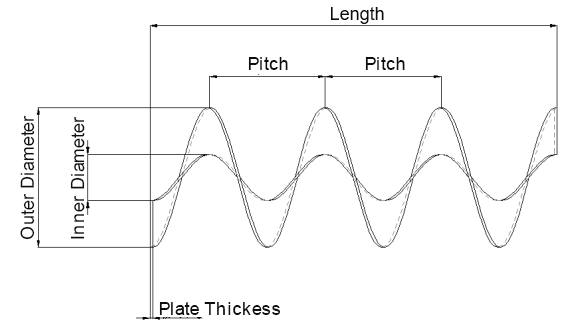

Within the scope of meeting the following table, customized production according to customer requirements.

|

Inner hole plate thickness (mm) |

Minimum inner diameter (mm) |

Maximum outer diameter (mm) |

Maximum radius difference (mm) |

Pitch outer diameter ratio | Outer diameter inner diameter ratio |

| 3.0 | 20 | 500 | 165 | 0.6-1.3 | 4.0 |

| 3.5 | 20 | 500 | 165 | 0.6-1.3 | 4.0 |

| 4.5 | 28 | 500 | 165 | 0.75-1.3 | 4.0 |

| 5.0 | 28 | 500 | 165 | 0.8-1.3 | 4.0 |

| 6.0 | 40 | 500 | 165 | 0.8-1.2 | 4.0 |

Emarks:

1. If the inner diameter of the customized specification is required to be within the range of the minimum inner diameter + 5mm, the maximum outer diameter of the specification cannot exceed 3 times the inner diameter.

2. For orders whose plate thickness is not within the range of the above table, due to material preparation reasons, the product weight for one order must be greater than 15 tons.

3. For other situations, please contact our company for detailed consultation, the hotline 400 086 6258.

- Recommended Products-

Welcome your message, we will give you feedback as soon as possible.

National Free Service Hotline

Tel: +86-511-88886257

Fax: +86-511-84521010

Q Q: 307944878

E-mail: market@banghe.com.cn

Add: No. 6, Yile Road, High-tech Park, Dantu District, Zhenjiang City, Jiangsu Province

Welcome to follow us

Mobile Website

WeChat Public Account

Follow Douyin

Follow Kuaishou

Copyright © 2020 Zhenjiang Banghe Spiral Manufacturing Co., Ltd. Powered by:www.300.cn 苏ICP备20029598号-1

Copyright © 2020 Zhenjiang Banghe Spiral Manufacturing Co., Ltd.

Powered by:www.300.cn 苏ICP备20029598号-1